TUBULAR MOULDS

The development of continuous casting has turned copper moulds into one of the main components required by the producer to attain his goals in terms of quality and productivity.

The evolution of ever more sophisticated materials which contribute to increase the products’life and improve its performances, together with the most recent studies to determine the optimal taper, has brought the copper mould to the cutting edge of modern technology.

Its features are specific to each production unit and designed in close consultation with the end user.

EM Moulds can provide any size and shape of copper mould tube aiming to reduce production costs, improve the steel quality and guarantee hassle free operations.

GROOVED MOULD TUBE

This new solution developed by EM MOULDS has demonstrated to improve the steel surface quality and reduce the shape defects especially in open stream

casting.

The grooves in the upper part of the mould tube internal wall optimize the cooling and the heat extraction from the steel around the meniscus area.

As a consequence a reduction of shape defects such as rhomboidity can be achieved, in some cases with an extended mould life. Moreover this solution helps to reduce the breakout rate and allows a more uniform shell growth.

SPECIAL APPLICATIONS

In order to meet any Customer’s requirements, EM MOULDS is available to supply any mould tube geometry with any technical requirement.

CHROMIUM COATING

EM MOULDS offers the guarantee of a knowhow which has been fully tested and improved during the past 50 years. The chromium coating technology has advanced considerably in recent past, as EM MOULDS has developed and installed the new coating facility which ensures a constant chromium deposition in every area of the mould (including corners) thanks to a controlled chromium flow.

The development of ever more performing tooling design has also contributed to improve the uniformity of the deposition.

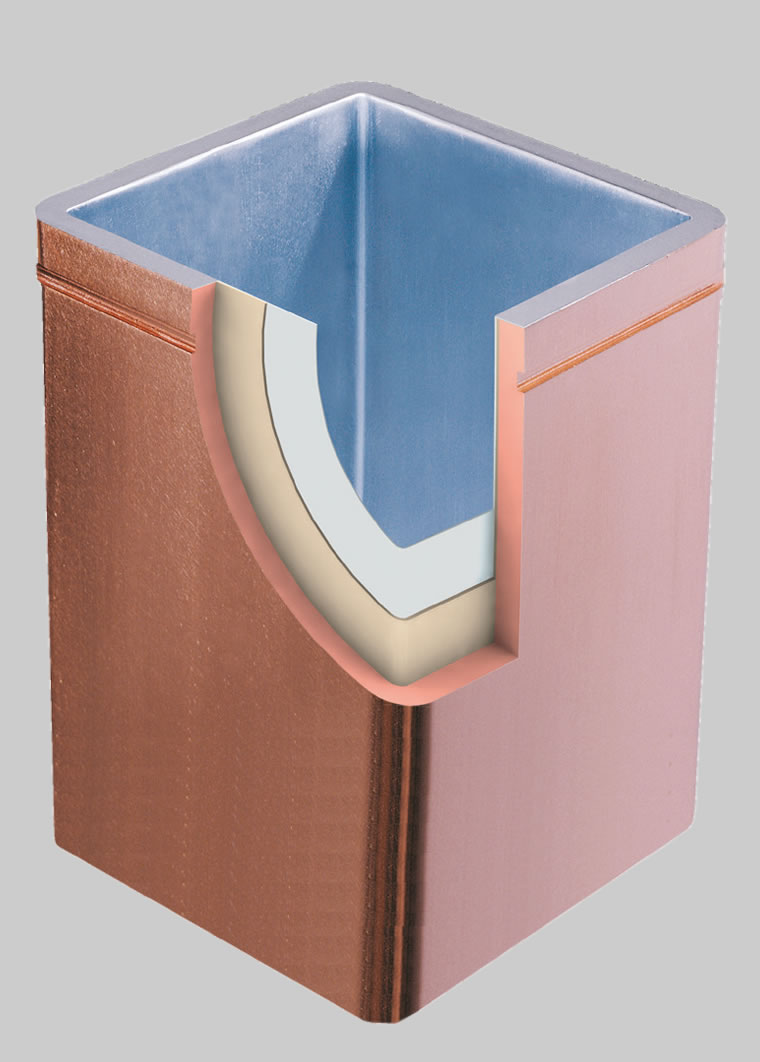

EM NICKEL CHROMIUM COATING

The Nickel Chrome coating consists of a double layer coating of nickel and chrome. The component in contact with the copper hot face is a nickel alloy, which is then overlaid with a layer of hard chrome.

The idea to apply an intermediate layer of nickel has the focus to increase mould life avoiding the formation of cracks in the chrome layer, especially at the meniscus.

The nickel alloy, in fact, has a coefficient of thermal expansion that is almost half way between thermal expansion coefficients of copper and chrome.

Therefore, the nickel alloy coating is better able to tolerate the greater expansion of the copper that takes place in the meniscus area during the casting process.

The presence of the nickel layer prevents the contamination of the copper substrate with components from the molten steel and/or casting lubricants such as sulphur or zinc, hence avoiding for example brass formation.

Comparative field tests in a number of steel plants have confirmed a significant increase in the average life of mould tubes plated with the EM MOULDS NC coating.