Services

Technical after sales

As well as the engineering and manufacturing of copper mould tubes and plates EM MOULDS provides to its customers a complete range of services aimed to improve the quality of the cast steel and increase the productivity.

The technical after sales – thanks to the wide experience in the field – distinguishes EM MOULDS from all other competitors.

Our team of metallurgical experts and technical assistants are always available to visit the Customers’ plants in order to promote continuous improvements and process efficiency.

Not only a copper mould supplier but a reliable partner in steel production.

RESEARCH AND DEVELOPMENT

Nowadays companies need to meet the challenges imposed by toughening competition, more stringent demand and new markets.

EM MOULDS constant investments in its Research Center aim to improve existing products developing new materials and technologies.

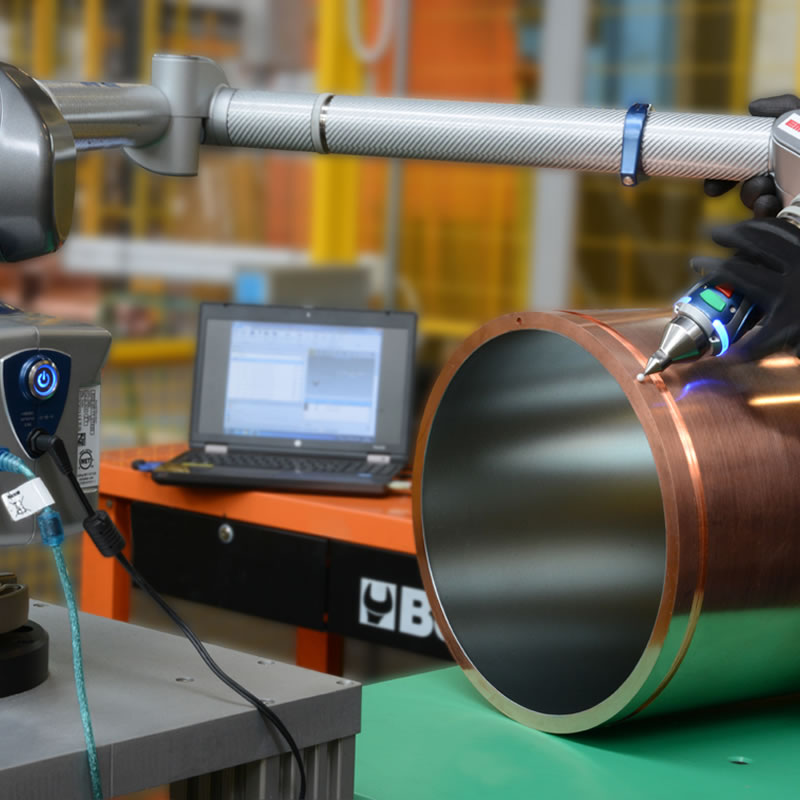

The state of the art equipment include:

- scanning Electron Microscope (SEM)

- energy Dispersive Spectrometer (EDS)

- high temperature tensile strength measurement equipment

- X-ray scan

ENGiNEERING

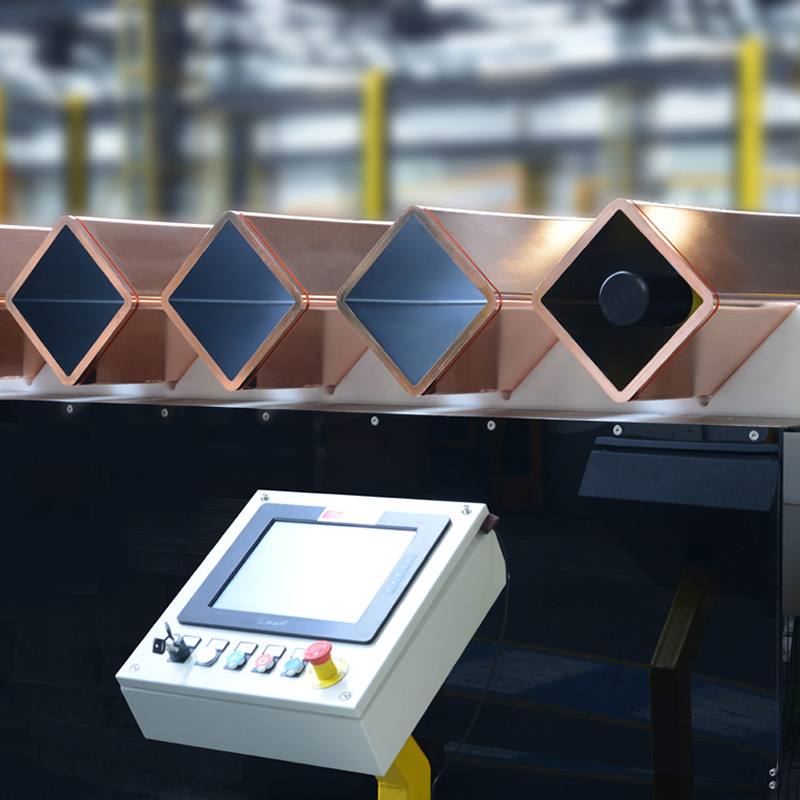

The copper mould is one of the most important components of a continuous casting machine.

Whilst giving the desired shape to the steel in production it should ensure the optimal skin growth in order to contain the liquid steel during the solidification process, therefore avoiding internal or superficial defects.

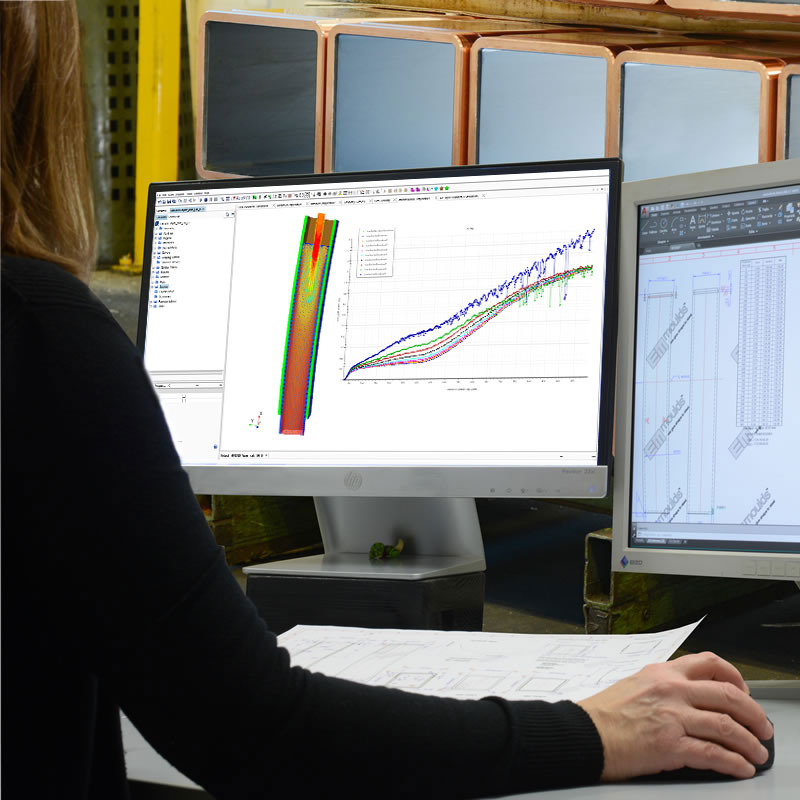

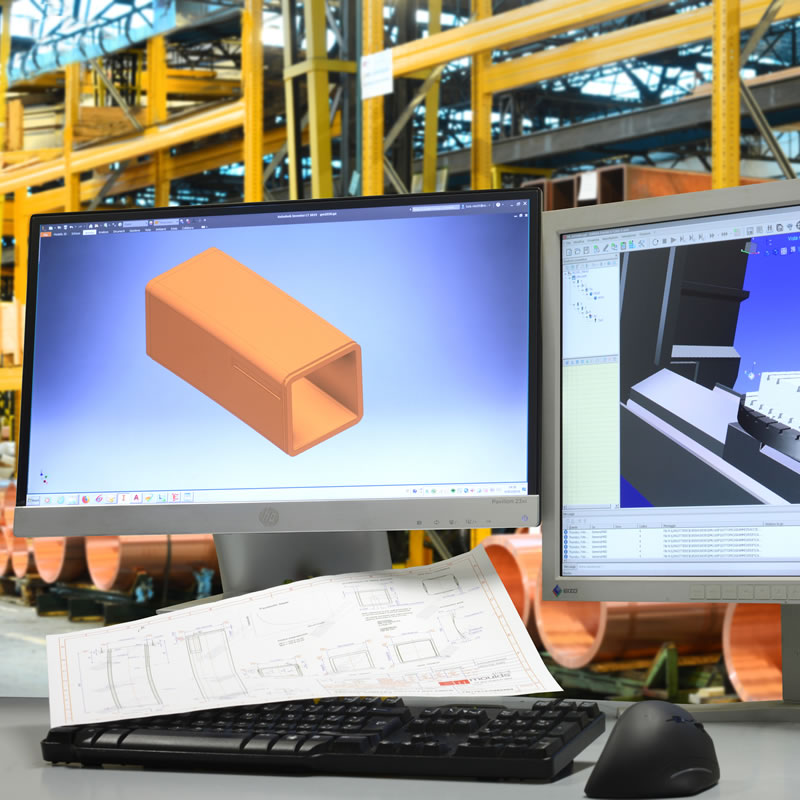

It is extremely important to design the mould considering all variables and casting practices that may affect the steel production and quality.

With more than 50 years of experience in the field, EM MOULDS is able to design the most suitable solution for each plant. Every mould design is based on computer aided analyses and simulations – which enable the study of the thermal heat exchange and the steel solidification along the mould – as well as on site trials results.. This tailor made approach to suit he required productivity and steel quality is key to EM MOULDS success worldwide.